Renaissance Process Digital Twin | Drive Intelligence

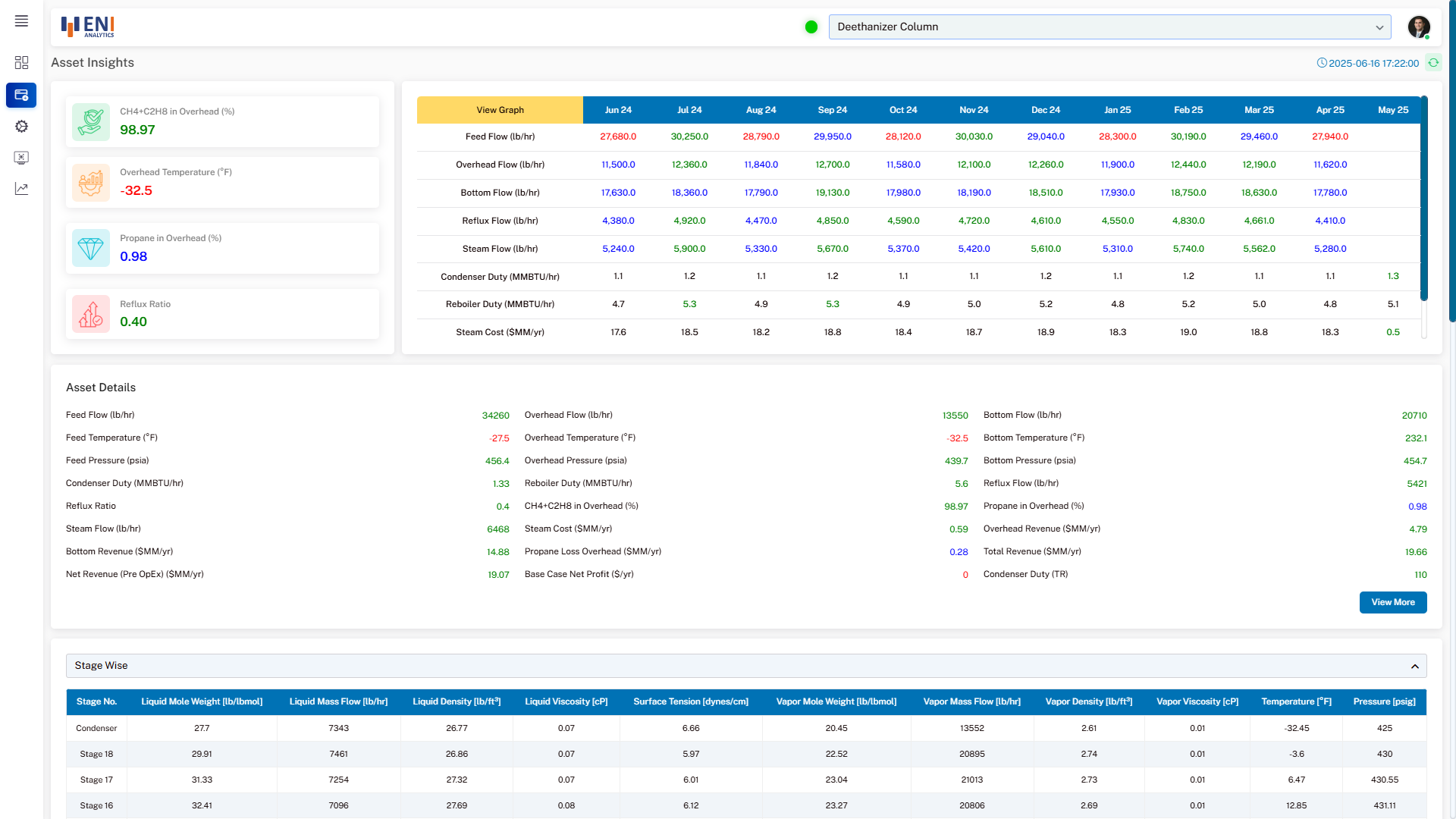

Go Beyond Visualization

Renaissance Process Digital Twin transforms your process plant into a real-time, intelligent system. Monitor critical KPIs, detect inefficiencies, and predict failures before they impact production. Built on advanced analytics and a secure, high-fidelity virtual environment, it empowers you to maximize uptime, optimize performance, and lead continuous improvement with confidence.

Contact Us